HART chainsaws are renowned for their reliability and efficiency in various cutting applications. To maintain their optimal performance, it is crucial to have access to high-quality replacement parts. This introduction will provide an overview of HART chainsaw parts, highlighting their importance and the benefits of using genuine replacements.

Maximizing Hart Chainsaw Efficiency with Regular Part Maintenance

Maintaining the optimal performance of your Hart chainsaw requires regular part maintenance. By replacing worn or damaged components, you can ensure that your chainsaw operates efficiently and safely.

One of the most critical parts to monitor is the chainsaw chain. A dull or damaged chain can significantly reduce cutting efficiency and increase the risk of kickback. Regularly sharpen or replace the chain to maintain its sharpness and prevent premature wear.

Another essential component is the guide bar. The guide bar provides support for the chain and helps guide it through the wood. Inspect the guide bar for any cracks or damage, and replace it if necessary. Additionally, ensure that the bar is properly lubricated to reduce friction and extend its lifespan.

The air filter plays a crucial role in protecting the engine from dust and debris. A clogged air filter can restrict airflow, leading to engine overheating and reduced performance. Regularly clean or replace the air filter to maintain optimal engine function.

The spark plug is responsible for igniting the fuel-air mixture in the engine. A worn or fouled spark plug can cause difficulty starting or poor engine performance. Replace the spark plug according to the manufacturer’s recommendations to ensure reliable ignition.

Other parts that may require periodic replacement include the recoil starter, fuel lines, and carburetor. By addressing these components proactively, you can prevent unexpected breakdowns and extend the overall lifespan of your Hart chainsaw.

Regular part maintenance is essential for maximizing the efficiency and safety of your Hart chainsaw. By replacing worn or damaged components, you can ensure that your chainsaw operates at its peak performance, reducing the risk of accidents and costly repairs.

Remember to consult the manufacturer’s instructions for specific maintenance intervals and replacement procedures. By following these guidelines, you can keep your Hart chainsaw in optimal condition for years to come.

Maintaining Hart Chainsaws: A Guide to Part Inspection and Replacement

Hart chainsaws are renowned for their reliability and durability. However, like any power tool, they require regular maintenance to ensure optimal performance and longevity. One crucial aspect of chainsaw maintenance is the inspection and replacement of parts. This guide will provide a comprehensive overview of the key parts to inspect and replace, along with step-by-step instructions for their removal and installation.

Part Inspection

Regularly inspecting your Hart chainsaw is essential for identifying potential issues early on. The following parts should be checked thoroughly:

- Chain: Inspect the chain for any signs of wear, such as dull or damaged teeth. A dull chain will reduce cutting efficiency and increase the risk of kickback.

- Bar: Examine the bar for any bends, cracks, or excessive wear. A damaged bar can compromise the safety and performance of the chainsaw.

- Spark plug: Check the spark plug for fouling or damage. A faulty spark plug can prevent the engine from starting or running smoothly.

- Air filter: Inspect the air filter for any dirt or debris that may restrict airflow. A clogged air filter can lead to engine overheating and reduced power.

- Fuel filter: Examine the fuel filter for any blockages or contamination. A dirty fuel filter can restrict fuel flow and cause engine problems.

Part Replacement

If any of the inspected parts show signs of wear or damage, they should be replaced promptly. Here are the steps involved in replacing common chainsaw parts:

- Chain: To replace the chain, loosen the chain tensioner and remove the old chain. Install the new chain and adjust the tension according to the manufacturer’s instructions.

- Bar: To replace the bar, remove the chain and loosen the bar nuts. Slide the old bar out and insert the new bar. Tighten the bar nuts securely.

- Spark plug: To replace the spark plug, remove the spark plug wire and unscrew the old spark plug. Install the new spark plug and tighten it to the specified torque.

- Air filter: To replace the air filter, remove the air filter cover and take out the old filter. Insert the new filter and reinstall the cover.

- Fuel filter: To replace the fuel filter, disconnect the fuel line and remove the old filter. Install the new filter and reconnect the fuel line.

Conclusion

Regular inspection and replacement of parts are crucial for maintaining the performance and safety of your Hart chainsaw. By following the steps outlined in this guide, you can ensure that your chainsaw operates at its best and provides years of reliable service. Remember to consult the manufacturer’s instructions for specific details and safety precautions related to your particular chainsaw model.

Comprehensive Guide to Hart Chainsaw Bar and Chain Replacement

Maintaining a Hart chainsaw requires regular replacement of its bar and chain to ensure optimal performance and safety. This guide provides a step-by-step process to help you replace these components effectively.

Materials Required:

- New Hart chainsaw bar

- New Hart chainsaw chain

- Chain tensioning tool

- Safety glasses

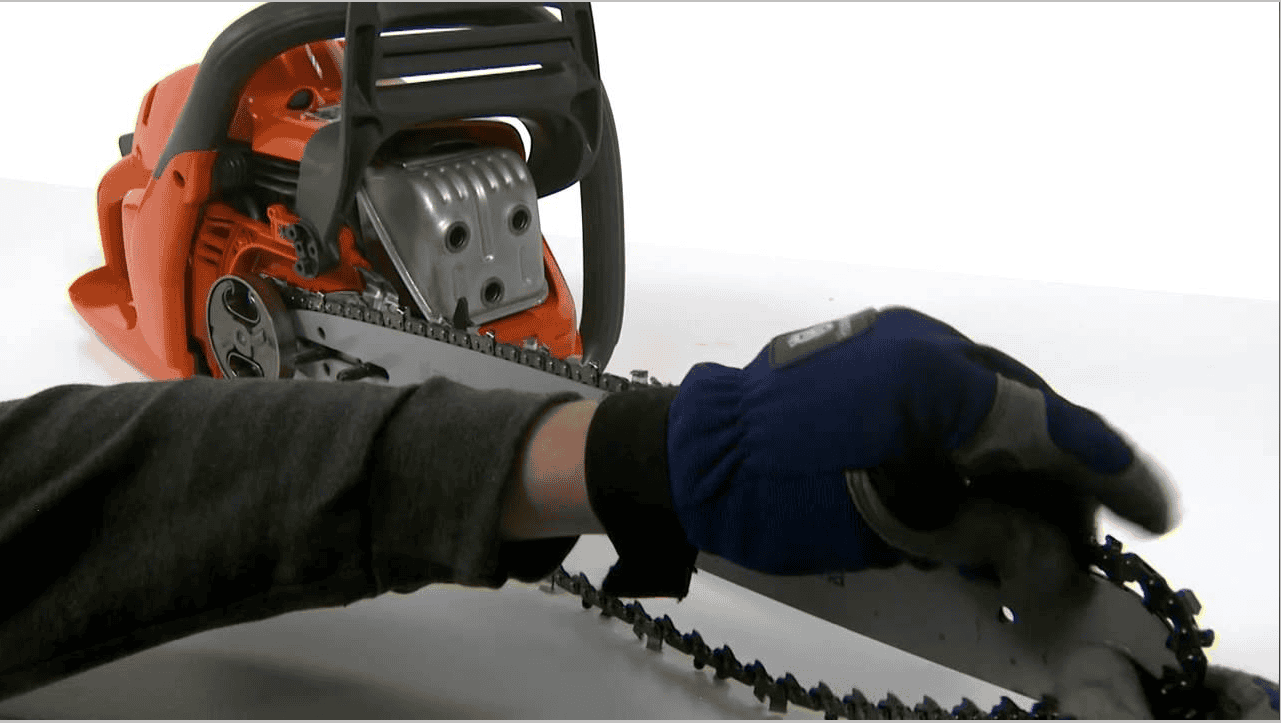

- Gloves

Step 1: Safety Precautions

Before starting, ensure you wear safety glasses and gloves to protect yourself from flying debris and sharp edges. Disconnect the chainsaw from its power source and allow it to cool down completely.

Step 2: Remove the Old Bar and Chain

- Loosen the chain tensioning screw using the chain tensioning tool.

- Remove the chain from the bar by pulling it off the sprocket.

- Remove the bar by unscrewing the nuts that secure it to the chainsaw body.

Step 3: Install the New Bar

- Align the new bar with the chainsaw body and insert it into the mounting holes.

- Secure the bar by tightening the nuts firmly.

Step 4: Install the New Chain

- Place the new chain around the bar, starting with the drive links.

- Ensure the chain is oriented correctly, with the cutting teeth facing the correct direction.

- Connect the chain to the sprocket and pull it through the bar.

Step 5: Tension the Chain

- Tighten the chain tensioning screw until the chain is snug but not overly tight.

- Use the chain tensioning tool to adjust the tension as needed.

- The chain should have approximately 1/16 inch of play between the bar and the bottom of the chain.

Step 6: Lubricate the Chain

- Apply a generous amount of chainsaw oil to the chain and bar.

- This will help reduce friction and extend the life of the components.

Step 7: Test the Chainsaw

- Reconnect the chainsaw to its power source and start it.

- Allow the chainsaw to run for a few minutes to ensure the chain is properly tensioned and lubricated.

- If necessary, adjust the chain tension or lubrication as needed.

Tips:

- Use only genuine Hart chainsaw parts to ensure compatibility and performance.

- Replace the bar and chain regularly to maintain optimal cutting efficiency.

- Keep the chainsaw clean and well-maintained to extend its lifespan.

- If you encounter any difficulties during the replacement process, consult a qualified technician for assistance.Upgrading Hart Chainsaw Performance with Replacement Parts

Upgrading Hart Chainsaw Performance with Replacement Parts

Hart chainsaws are renowned for their reliability and efficiency. However, like any tool, they may require occasional maintenance or upgrades to maintain optimal performance. Replacing certain parts can significantly enhance the chainsaw’s capabilities and extend its lifespan.

One crucial component to consider is the guide bar. A worn or damaged guide bar can hinder cutting efficiency and increase the risk of kickback. Replacing it with a new one ensures a smooth and precise cut. Additionally, upgrading to a longer guide bar can increase the chainsaw’s cutting capacity, making it suitable for larger logs.

Another essential part is the chain. A dull or damaged chain can significantly reduce cutting speed and increase the effort required to operate the chainsaw. Replacing the chain with a sharp one not only improves cutting efficiency but also reduces wear and tear on the guide bar. Consider using a high-quality chain with a durable design to withstand heavy-duty use.

The air filter plays a vital role in protecting the engine from dust and debris. A clogged air filter can restrict airflow, leading to reduced power and increased fuel consumption. Regularly replacing the air filter ensures optimal engine performance and extends its lifespan.

The spark plug is another critical component that affects the chainsaw’s performance. A worn or fouled spark plug can cause ignition problems, resulting in difficulty starting or running the chainsaw. Replacing the spark plug with a new one ensures a reliable ignition and smooth operation.

Upgrading the carburetor can also significantly improve the chainsaw’s performance. A properly tuned carburetor ensures the correct fuel-to-air ratio, resulting in increased power and efficiency. Replacing the carburetor with a high-performance model can further enhance the chainsaw’s capabilities.

Finally, consider replacing the recoil starter if it becomes difficult to pull or fails to engage the engine. A new recoil starter ensures a reliable and effortless start-up.

By replacing these key parts, you can significantly upgrade the performance of your Hart chainsaw. Not only will it cut more efficiently and effectively, but it will also be more reliable and durable. Regular maintenance and timely replacement of worn or damaged parts will ensure that your chainsaw continues to perform at its best for years to come.

Troubleshooting Common Hart Chainsaw Part Failures

Hart chainsaws are renowned for their reliability and durability. However, like any mechanical device, they can experience occasional part failures. Understanding the common causes of these failures can help you diagnose and resolve issues promptly, ensuring optimal performance and safety.

Chain and Bar Failures

The chain and bar are essential components that experience significant wear and tear during operation. A dull chain can reduce cutting efficiency, while a damaged bar can compromise safety. Regular sharpening and replacement of the chain are crucial to maintain optimal performance. Additionally, inspect the bar for any cracks or bends, and replace it if necessary.

Spark Plug Issues

A faulty spark plug can prevent the chainsaw from starting or cause it to run erratically. Inspect the spark plug for any damage or fouling. Clean or replace the spark plug as needed to ensure proper ignition.

Fuel System Problems

Fuel-related issues can also lead to chainsaw failures. A clogged fuel filter can restrict fuel flow, while a faulty carburetor can cause improper fuel mixture. Clean or replace the fuel filter regularly, and consider having the carburetor serviced by a qualified technician if you suspect any issues.

Air Filter Blockage

A dirty air filter can restrict airflow to the engine, leading to performance problems. Clean or replace the air filter regularly to ensure adequate air intake.

Starter Cord Issues

The starter cord is a common point of failure on Hart chainsaws. If the cord breaks or becomes frayed, it can prevent you from starting the chainsaw. Replace the starter cord with a new one of the appropriate length and diameter.

Other Common Failures

Other potential part failures include:

- Clutch problems: A worn or damaged clutch can cause the chain to slip or engage improperly.

- Oil pump issues: A faulty oil pump can result in insufficient lubrication of the chain and bar, leading to premature wear.

- Electrical failures: Electrical components, such as the ignition coil or wiring, can fail over time, causing the chainsaw to malfunction.

Preventive Maintenance

Regular maintenance is essential to prevent part failures and extend the lifespan of your Hart chainsaw. Follow the manufacturer’s recommended maintenance schedule, including:

- Cleaning and lubricating the chain and bar

- Inspecting and replacing the spark plug

- Cleaning the fuel filter and carburetor

- Replacing the air filter

- Checking the starter cord for wear and tear

By addressing common part failures promptly and implementing preventive maintenance practices, you can ensure the reliable and efficient operation of your Hart chainsaw for years to come.

Essential Hart Chainsaw Parts for Optimal Performance

Maintaining a Hart chainsaw in peak condition requires the timely replacement of essential parts. Understanding the functions of these components is crucial for ensuring the chainsaw’s efficiency and longevity.

Guide Bar and Chain

The guide bar and chain are the primary cutting components of the chainsaw. The guide bar provides a track for the chain to run on, while the chain consists of sharp teeth that cut through wood. Regular sharpening and replacement of the chain are necessary to maintain optimal cutting performance.

Spark Plug

The spark plug ignites the fuel-air mixture in the engine, initiating the combustion process. A worn or fouled spark plug can lead to difficult starting, poor performance, and increased fuel consumption. Replacing the spark plug at recommended intervals is essential for smooth engine operation.

Air Filter

The air filter prevents dirt and debris from entering the engine, ensuring clean air intake. A clogged air filter can restrict airflow, leading to reduced power and increased engine wear. Regular cleaning or replacement of the air filter is crucial for maintaining engine health.

Fuel Filter

The fuel filter removes impurities from the fuel before it enters the carburetor. A dirty fuel filter can cause fuel starvation, resulting in engine stalling or poor performance. Replacing the fuel filter periodically ensures a clean fuel supply to the engine.

Carburetor

The carburetor mixes fuel and air in the correct proportions for combustion. A malfunctioning carburetor can cause engine problems such as flooding, surging, or hesitation. Regular cleaning or adjustment of the carburetor is essential for optimal engine performance.

Starter Rope

The starter rope is used to manually start the chainsaw engine. A frayed or broken starter rope can prevent the engine from starting. Replacing the starter rope when necessary ensures easy and reliable starting.

Other Essential Parts

In addition to the aforementioned components, other essential parts include the recoil starter, clutch, and chain tensioner. These parts play vital roles in the chainsaw’s operation and should be inspected and replaced as needed.

Regular Maintenance and Replacement

Regular maintenance and timely replacement of essential Hart chainsaw parts are crucial for ensuring optimal performance and extending the chainsaw’s lifespan. By understanding the functions of these components and adhering to recommended maintenance schedules, users can keep their Hart chainsaws operating efficiently and safely.

HART chainsaw parts and replacement parts are widely available and affordable, making it easy to maintain and repair your HART chainsaw. The availability of genuine HART parts ensures compatibility and optimal performance, while aftermarket parts offer cost-effective alternatives. By utilizing the right parts, you can extend the lifespan of your HART chainsaw and ensure its continued reliability.