Modifying a chainsaw ripping chain involves altering the shape and configuration of the chain’s teeth to optimize it for ripping cuts, which are cuts made parallel to the wood grain. This process requires specialized tools and techniques to ensure proper performance and safety. In this article, we will provide a comprehensive guide on how to modify a chainsaw ripping chain, including the necessary tools, step-by-step instructions, and tips for achieving the best results.

Troubleshooting Common Issues with Ripping Chains

Chainsaw ripping chains are specifically designed for cutting straight lines in wood, making them ideal for tasks such as milling lumber and cutting firewood. However, to achieve the best results, it is often necessary to modify the chain to suit the specific application.

Step 1: Determine the Desired Cut Width

The first step is to determine the desired cut width. This will depend on the thickness of the wood being cut and the intended use of the lumber. For general-purpose ripping, a cut width of 1/2 inch to 3/4 inch is typically sufficient.

Step 2: Grind the Cutters

Once the cut width has been determined, the cutters on the chain need to be ground to the appropriate angle. For ripping, the cutters should be ground to a 10-degree angle on the top and a 30-degree angle on the side. This angle combination provides a clean, straight cut with minimal tear-out.

Step 3: Adjust the Raker Depth

The rakers on the chain are responsible for controlling the depth of the cut. For ripping, the rakers should be set to a depth of approximately 0.025 inches below the top of the cutters. This will ensure that the chain cuts smoothly and efficiently without binding.

Step 4: Sharpen the Chain

After modifying the cutters and rakers, the chain should be sharpened to ensure optimal performance. Use a chainsaw file guide to maintain the correct angle and depth of the cutting teeth.

Step 5: Test the Chain

Once the chain has been modified and sharpened, it is important to test it on a piece of scrap wood to ensure that it is cutting properly. Make adjustments to the cutter angle, raker depth, or sharpening as needed until the desired results are achieved.

Additional Tips:

- Use a high-quality chainsaw chain specifically designed for ripping.

- Keep the chain properly lubricated to reduce friction and extend its lifespan.

- Inspect the chain regularly for wear and damage, and replace it as necessary.

- Wear appropriate safety gear when operating a chainsaw, including eye protection, earplugs, and gloves.

By following these steps, you can modify a chainsaw ripping chain to achieve the best possible results for your specific application. Remember to always prioritize safety and use proper techniques to ensure a successful and efficient cutting experience.

Safety Precautions for Modifying Ripping Chains

Modifying a chainsaw ripping chain requires meticulous attention to safety protocols to prevent injuries and ensure optimal performance. Before embarking on this task, it is imperative to adhere to the following precautions:

1. Wear Appropriate Protective Gear:

Don protective clothing, including a helmet, safety glasses, earplugs, gloves, and sturdy boots. These will shield you from flying wood chips, sparks, and noise.

2. Secure the Chainsaw:

Place the chainsaw on a stable surface and engage the chain brake to prevent accidental activation. Ensure the power cord is disconnected or the fuel tank is empty.

3. Use Sharp Tools:

Utilize sharp files and grinders to modify the chain. Dull tools can cause the chain to bind or break, posing a safety hazard.

4. Maintain a Proper Grip:

Hold the file or grinder firmly and securely. Avoid applying excessive pressure, as this can damage the chain or cause it to slip.

5. File in the Correct Direction:

File the teeth in the direction of the chain’s rotation. Filing in the opposite direction can weaken the teeth and increase the risk of breakage.

6. Maintain Proper Angles:

Follow the manufacturer’s recommendations for the correct filing angles. Incorrect angles can compromise the chain’s cutting efficiency and durability.

7. Check for Overheating:

Regularly check the chain for overheating. If the chain becomes too hot, stop filing and allow it to cool down. Overheating can damage the chain’s temper and reduce its lifespan.

8. Test the Chain:

After modifying the chain, test it on a piece of scrap wood to ensure it cuts smoothly and efficiently. If any adjustments are necessary, repeat the filing process until the desired results are achieved.

9. Store the Chain Properly:

When not in use, store the modified chain in a dry, protected location. Apply a light coating of oil to prevent rust and corrosion.

By adhering to these safety precautions, you can minimize the risks associated with modifying a chainsaw ripping chain and ensure a safe and productive experience.

Lubrication and Maintenance for Ripping Chains

Chainsaw ripping chains are specifically designed for cutting through thick lumber with precision and efficiency. However, to achieve the best results, it is essential to modify the chain to suit your specific needs. Here’s a comprehensive guide on how to modify a chainsaw ripping chain:

Step 1: Determine the Desired Cutting Width

The first step is to determine the desired cutting width. This will depend on the thickness of the lumber you will be cutting. For most applications, a cutting width of 0.050 inches to 0.063 inches is ideal.

Step 2: Grind the Depth Gauges

Depth gauges are small metal tabs located on the top of the chain teeth. They control the depth of the cut. To modify the chain for ripping, you need to grind the depth gauges to the desired cutting width. Use a flat file or a depth gauge grinder to carefully remove material from the gauges.

Step 3: Sharpen the Cutters

Once the depth gauges are set, you need to sharpen the cutters. Use a chainsaw file or a sharpening stone to sharpen the cutters to a 30-degree angle. Ensure that the cutters are sharp and free of any burrs.

Step 4: Adjust the Raker Angle

The raker angle is the angle at which the rakers are set. Rakers are small metal tabs located behind the cutters. They prevent the chain from cutting too deeply into the wood. To modify the chain for ripping, you need to adjust the raker angle to 10 degrees. Use a raker gauge to set the angle accurately.

Step 5: Lubricate the Chain

Proper lubrication is crucial for the longevity and performance of the chain. Use a high-quality chainsaw oil to lubricate the chain before and after each use. This will reduce friction and prevent premature wear.

Step 6: Test the Chain

Once the chain is modified, test it on a piece of scrap wood. Make sure that the chain cuts smoothly and efficiently. If necessary, make further adjustments to the depth gauges, cutters, or raker angle until you achieve the desired results.

Conclusion

Modifying a chainsaw ripping chain is a relatively simple process that can significantly improve its performance. By following these steps, you can ensure that your chain is properly set up for ripping lumber with precision and efficiency. Remember to always wear appropriate safety gear when working with chainsaws and to follow the manufacturer’s instructions for proper maintenance and operation.

Adjusting Chain Tension for Optimal Ripping

Chainsaw ripping chains are specifically designed for cutting wood along the grain, resulting in smooth, precise cuts. However, to achieve optimal performance, it is crucial to modify the chain correctly. Here’s a comprehensive guide to help you modify your chainsaw ripping chain:

Step 1: Safety Precautions

Before commencing any modifications, ensure your safety by wearing appropriate protective gear, including gloves, safety glasses, and earplugs. Disconnect the spark plug to prevent accidental starting.

Step 2: Sharpening the Teeth

Ripping chains require sharp teeth to cut efficiently. Use a chainsaw file to sharpen the teeth to a 30-degree angle. File the teeth in an alternating pattern, starting with the left-hand tooth and then the right-hand tooth.

Step 3: Setting the Rakers

Rakers are small metal tabs located in front of the cutting teeth. They control the depth of the cut. For ripping, the rakers should be set to a height of 0.025 inches (0.635 mm) below the cutting teeth. Use a raker gauge to ensure accuracy.

Step 4: Adjusting the Chain Tension

Proper chain tension is essential for safe and efficient operation. Adjust the chain tension by loosening the chain tensioner bolts and turning the tensioning screw until the chain is snug but not overly tight. The chain should have approximately 1/4 inch (6.35 mm) of play when pulled at the midpoint between the bar and the chain.

Step 5: Lubricating the Chain

Lubrication is crucial for reducing friction and extending the life of the chain. Use a high-quality chainsaw oil and apply it liberally to the chain and bar.

Step 6: Testing the Chain

Once the chain is modified, test it on a piece of scrap wood. Make a few cuts to ensure that the chain is cutting smoothly and efficiently. If necessary, make further adjustments to the sharpening, rakers, or chain tension.

Additional Tips:

- Use a ripping chain specifically designed for your chainsaw model.

- Keep the chain sharp and well-maintained for optimal performance.

- Inspect the chain regularly for any damage or wear.

- Replace the chain when it becomes dull or damaged to prevent accidents.

By following these steps, you can effectively modify your chainsaw ripping chain for optimal performance. Remember to prioritize safety and use the correct tools and techniques to ensure a successful modification.

Selecting the Right Ripping Chain for Your Needs

Chainsaw ripping chains are specifically designed for cutting through thick lumber with precision and efficiency. Modifying a standard chainsaw chain to create a ripping chain requires careful consideration and the right tools. Here’s a comprehensive guide to help you select the best ripping chain for your needs:

Chain Pitch and Gauge:

The chain pitch refers to the distance between the drive links, while the gauge indicates the thickness of the drive links. For ripping, a chain with a narrow pitch (e.g., 3/8″ or .325″) and a thick gauge (e.g., .050″ or .058″) is ideal. This combination provides stability and reduces kickback.

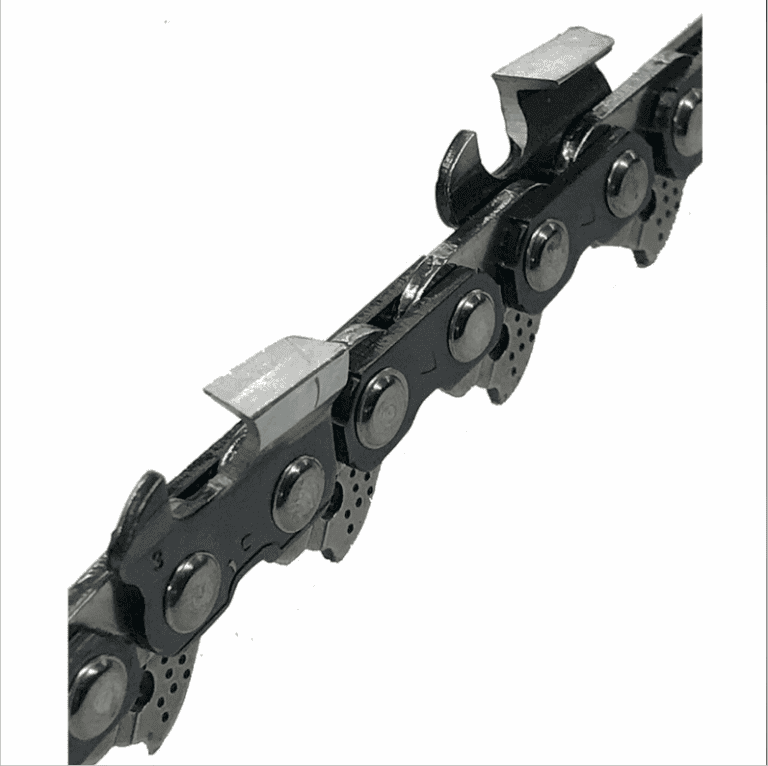

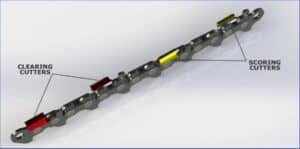

Tooth Design:

Ripping chains feature specialized tooth designs that optimize cutting performance. Look for chains with chisel-shaped teeth that have a sharp top plate and a raker tooth that limits the depth of cut. This design ensures clean, straight cuts with minimal tear-out.

Chain Length:

The length of the chain depends on the size of your chainsaw bar. Measure the length of the bar from the tip to the base and select a chain that matches or slightly exceeds this measurement. A longer chain can provide more cutting capacity, but it may also increase the risk of kickback.

Material:

Ripping chains are typically made from high-quality steel alloys that offer durability and resistance to wear. Look for chains that are heat-treated for added strength and longevity.

Modification Process:

Modifying a standard chainsaw chain into a ripping chain involves grinding down the depth gauges of the teeth. This process requires a specialized grinding tool and should be performed by an experienced professional. The depth gauges should be reduced to a height of approximately 0.020″ to 0.030″.

Safety Precautions:

When modifying or using a ripping chain, always follow proper safety precautions. Wear appropriate protective gear, including gloves, eye protection, and hearing protection. Ensure that the chainsaw is properly maintained and sharpened before use.

Conclusion:

Selecting the right ripping chain for your needs is crucial for achieving optimal cutting performance and safety. By considering the chain pitch, gauge, tooth design, length, material, and modification process, you can choose a chain that meets your specific requirements. Remember to prioritize safety and consult with a professional if you are unsure about any aspect of the modification process.

Sharpening Techniques for Ripping Chains

Modifying a chainsaw ripping chain involves altering its cutting teeth to enhance its performance for ripping applications. This process requires specialized tools and techniques to ensure optimal results.

Step 1: Gather Necessary Tools

Before commencing, gather the following tools: a grinder with a cutoff wheel, a flat file, a round file, and a depth gauge.

Step 2: Remove Excess Depth

Using the grinder, carefully remove the excess depth from the rakers. Rakers are small teeth located in front of the cutters that control the depth of the cut. Reduce the raker height to approximately 0.025 inches.

Step 3: Sharpen the Cutters

Next, sharpen the cutters using a flat file. Hold the file at a 30-degree angle to the cutting edge and file in a forward motion. Maintain a consistent angle and pressure to ensure even sharpening.

Step 4: Round the Cutters

After sharpening the cutters, use a round file to round the corners of the cutting teeth. This helps prevent the chain from binding in the wood and improves its cutting efficiency.

Step 5: Set the Depth Gauge

Finally, set the depth gauge to the desired cutting depth. The depth gauge is a small metal tab that limits the depth of the cut. Adjust it to the appropriate height using a depth gauge tool.

Tips for Optimal Performance

- Use a high-quality grinder and files for precise results.

- Wear appropriate safety gear, including gloves and eye protection.

- Sharpen the chain regularly to maintain its cutting performance.

- Inspect the chain for any damage or wear before each use.

- Lubricate the chain properly to reduce friction and extend its lifespan.

Conclusion

Modifying a chainsaw ripping chain is a straightforward process that can significantly improve its performance for ripping applications. By following these steps and using the appropriate tools, you can ensure that your chain is sharp, efficient, and ready to tackle any ripping task. Remember to prioritize safety and maintain your chain regularly for optimal results.