If you’re a chainsaw enthusiast or a woodworker, you’ve probably heard about ripping chainsaw chains. These specialized chains are designed for milling lumber, allowing you to cut parallel to the wood grain. In this article, we’ll delve into what a ripping chain is, its advantages over standard chains, and most importantly, how to modify a regular chainsaw chain into a ripping chain.

What Is a Ripping Chainsaw Chain?

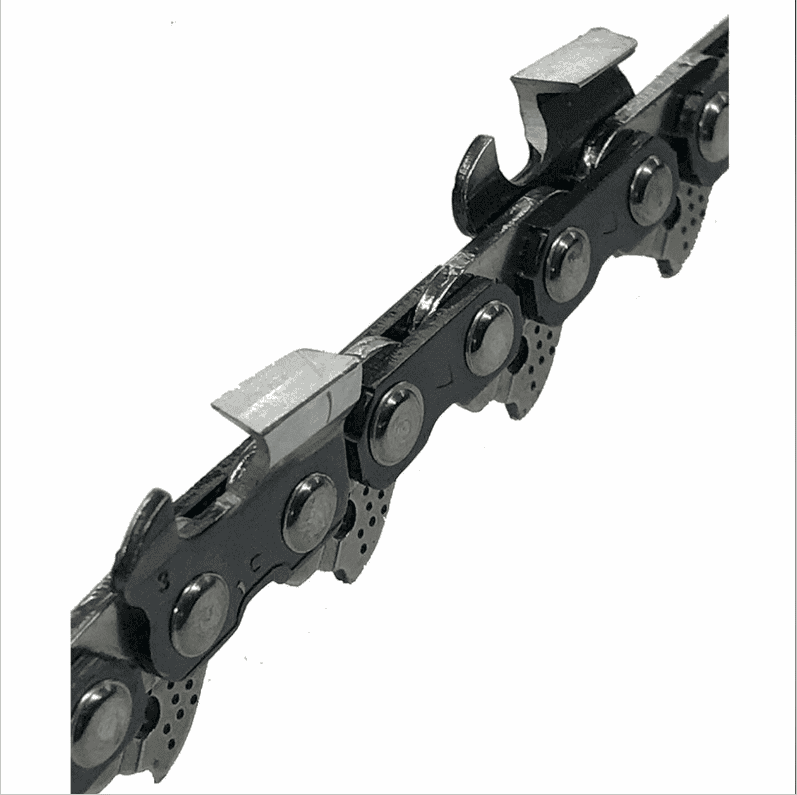

A ripping chainsaw chain is specifically optimized for cutting wood along the grain, making it ideal for milling purposes. Unlike standard chains, which are designed for crosscutting (perpendicular to the tree’s limb), ripping chains cut parallel to the wood fibers. Here are some key features of ripping chains:

- Smooth Cuts: Ripping chains create cleaner and smoother cuts when milling lumber.

- Durable Design: These chains are built to withstand the demands of milling without premature wear.

- Semi-Chisel Structure: Ripping chains have semi-chisel teeth, striking a balance between sharpness and durability.

How to Make a Ripping Chainsaw Chain?

What You Need:

- A standard chainsaw chain

- A flat file

- A depth gauge tool

- A vise or clamp to secure the chainsaw

Step-by-Step Guide:

- Measure the Depth Gauges (Rakers):

- Ripping chains typically have deeper depth gauges than standard chains.

- Use a depth gauge tool to measure the depth of the gauges.

- File them down to achieve the correct depth for ripping.

- File the Cutting Teeth:

- Use a flat file to sharpen the cutting teeth.

- Adjust the sharpening angle to be between 5 to 10 degrees (compared to the usual 25 to 35 degrees for crosscut chains).

- Maintain consistent pressure and motion while filing each tooth.

- Grind the Top Plate:

- The top plate of the cutting teeth should be ground to match the new sharpening angle.

- Use a specialized chainsaw file guide or jig for precise grinding.

- Adjust the Angles of the Cutting Teeth:

- Ensure that all cutting teeth have uniform angles.

- Consistent angles lead to better cutting efficiency.

- Check the Sharpness of the Chain:

- Test the chain’s sharpness by making a few test cuts on scrap wood.

- Adjust as needed to achieve optimal ripping performance.

Ripping Chain vs. Standard Chain: A Comparison

Ripping Chainsaw Chain:

- Smooth Cuts: Provides cleaner and smoother cuts.

- Durable Design: Built to withstand milling demands.

- Semi-Chisel Structure: Balances sharpness and durability.

Standard Chainsaw Chain:

- Cuts the Veins and Fiber: Designed for crosscutting.

- Versatility: Suitable for various cutting tasks.

Frequently Asked Questions:

- What Pitch Is a Ripping Chain?

- Ripping chains come in various pitches, similar to standard chains. Choose the one that matches your chainsaw.

- Will a Ripping Chain Make a Difference?

- Yes, it significantly improves milling efficiency.

- How Do You Differentiate Between a Regular and Ripping Chain?

- Look for the semi-chisel teeth and deeper depth gauges on a ripping chain.

- To What Degree Should You Sharpen a Ripping Chain?

- Sharpen between 5 to 10 degrees.

- What Is the Difference Between Micro Chisel and Semi Chisel?

- Micro chisel has sharper angles, while semi-chisel balances sharpness and durability.

- Does Stihl Make Ripping Chains?

- Yes, Stihl offers ripping chains for their chainsaws.

- What Are the Angles on the Stihl Ripping Chain?

- Stihl ripping chains have specific angles optimized for milling.

Final Words

Now that you know how to modify a chainsaw chain into a ripping chain, you can enhance your milling capabilities. Remember to follow safety precautions while working with chainsaws, and happy milling! 🌲🪚