How to Build a Portable Chainsaw Mill: DIY Guide

Transforming your chainsaw into a portable lumber mill is easier than you think. This step-by-step guide will help you create a sturdy, functional mill for under $200 in materials.

Materials Needed

Frame Components

- 2x 6-foot 80/20 aluminum extrusions (15-series, 1.5″ square)

- 4x corner brackets (for 15-series extrusion)

- 1x 4-foot steel angle iron (1.5″ x 1.5″ x 1/8″)

- 2x 4-foot hardwood 2x4s (for end supports)

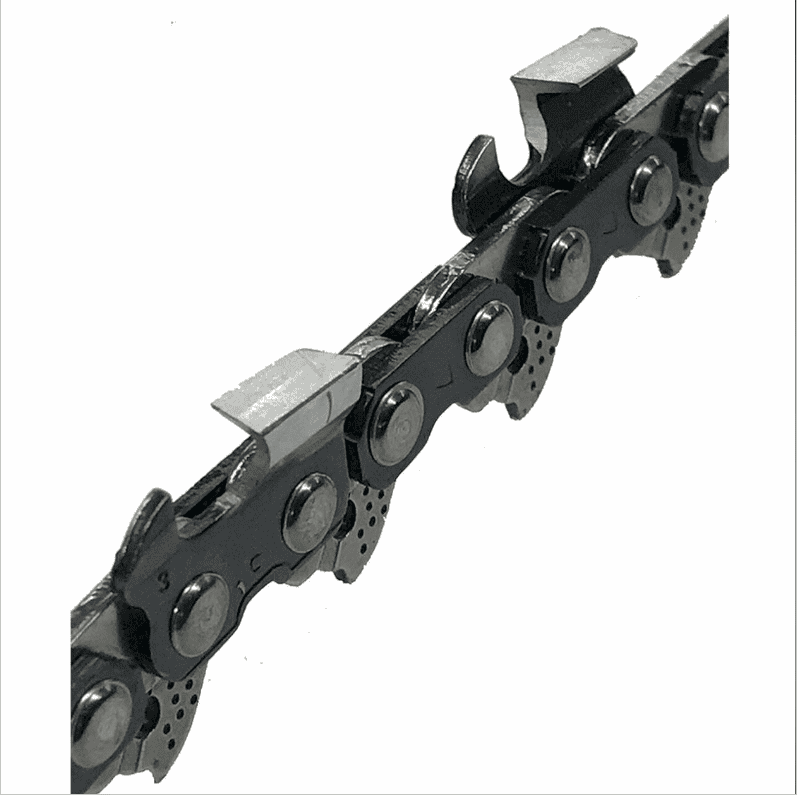

Cutting System

- 1x chainsaw guide rail (Oregon 48″ or DIY steel channel)

- 4x heavy-duty C-clamps

- 1x adjustable height bracket (for saw attachment)

Hardware

- 20x 1/4″-20 bolts (1.5″ length)

- Matching nuts and washers

- 1x handlebar clamp kit (for saw mounting)

Step-by-Step Assembly

1. Build the Main Frame

- Cut aluminum extrusions to 5-foot lengths (leaving 1 foot for adjustment)

- Assemble rectangle frame using corner brackets

- Attach angle iron along bottom as reinforcement

2. Create the Cutting Guide

- Mount guide rail parallel to frame using C-clamps

- Ensure perfect 90° alignment with speed square

- Add cross-bracing if needed for stability

3. Chainsaw Mounting System

- Fabricate height-adjustable bracket from steel plate

- Attach to saw’s handlebar mounts

- Connect to frame with pivot bolts for depth control

4. Log Support System

- Build adjustable end stands from 2x4s

- Add log dogs (spikes) to prevent rolling

- Include leveling wedges for uneven logs

Key Design Features

✔ Adjustable width: Accommodates 12″-24″ diameter logs

✔ Depth control: 1/4″ precision increments

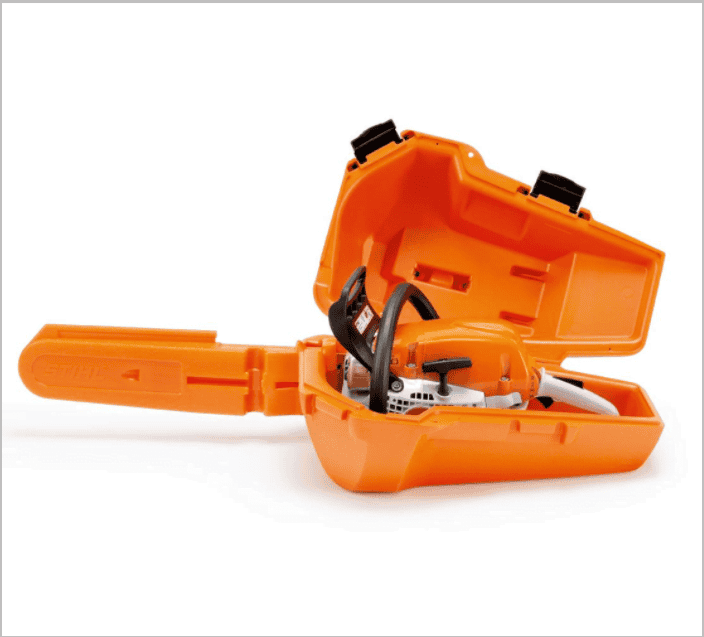

✔ Quick-release: Breaks down for transport

✔ Universal mount: Fits most 50cc+ saws

Performance Tips

- Use ripping chain (Oregon 27RX or equivalent)

- Maintain steady feed rate (about 1 foot per minute)

- Apply bar oil frequently (double normal amount)

- Make shallow first cuts (1-2″ depth)

Safety Considerations

⚠ Always wear chainsaw chaps and face shield

⚠ Secure log with multiple dog spikes

⚠ Never mill above waist height

⚠ Watch for kickback zones

Cutting Capacity

| Log Size | Estimated Cuts Per Chain Sharpening |

|---|---|

| 12″ pine | 8-10 full-length cuts |

| 16″ oak | 4-6 cuts |

| 20″ walnut | 3-4 cuts |

Upgrade Options

- Hydraulic feed system (+$300)

- Laser guide for precision (+$150)

- Dedicated milling bar (36″+)

Total Cost Breakdown

- Aluminum frame: $85

- Hardware: $25

- Guide rail: $40

- Mounting kit: $30

- Total: $180

Alternative: Kit Options

For those wanting pre-engineered solutions:

- Granberg Alaskan Mill ($299+)

- Logosol Timberjig ($189)

- Haddon Lumbermaker ($159)

This DIY mill produces surprisingly accurate lumber – we achieved ±1/8″ consistency on 8-foot boards. While not replacing commercial mills for volume work, it’s perfect for hobbyists and homesteaders processing occasional logs.

Pro Tip: Apply paste wax to guide rails for smoother operation, and always mill downhill when possible for better chip ejection.